-

-

Cutting corners and material utilization with advanced manufacturing methods.

-

-

We offer a multitude of finishing options. Here from our giant tumbler.

-

We can bend it.

-

Flat polymer sheets formed into function.

-

We can source and add value operations instead of making from scratch.

-

Secondary inspection, confidence that the parts are right

-

extensive design for assembly experience

-

Weld-less fabrication, formed polymers and dynamic door action closers without springs.

-

-

Industrial packaging appliances in production.

-

Here is a good example where we eliminated welding with creativity.

-

Before we ship we know it is right.

-

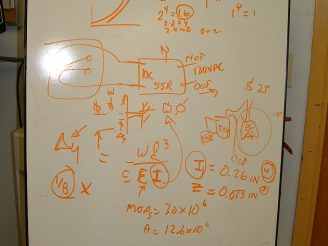

We are comfortable explain how we arrived at a solution.

-

Door wall drive, eliminated 80% of the weight and 75% of the bulk complexity

-

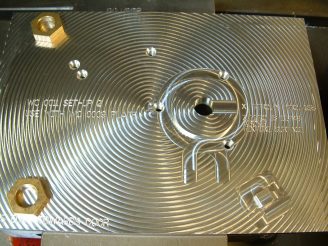

Fixed center sprockets, simple and rugged.

-

Advanced prototype machines, made in limited quantity.

-

-

Units in final assembly and QC. We don’t just invent, we build.

-

We get excited to ship qualified units out to the end user so they get to experience our attention to detail

-

At a moments notice we can make in-process changes or make prototypes.

-

Limited production prototypes

-

Door opening/closing problem fixed. We replaced the springs with one of our secret widgets. Creative reliability.

-

We can get fancy with fixtures.

-

Units in final assembly and QC. We don’t just invent, we build.